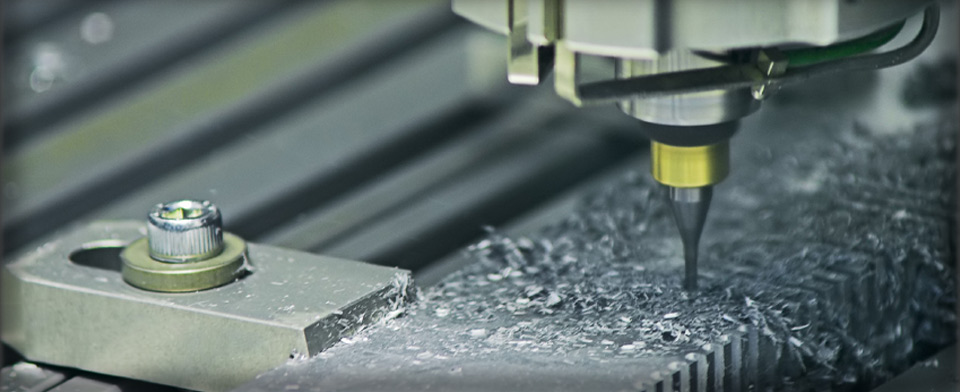

Thanks to CNC machining Riverside machine shops are capable of producing more accurate parts for lower cost and with better quality than anyone would expect from manual machining. CNC makes it possible for one machine to cut many different parts with no need for time-consuming machinists’ aids… and for the customer to order parts with unusual shapes and expect the same accuracy as they would for square ones.

CNC Machining Riverside

Computer Numerical Control (CNC) was invented shortly after WWII. Advances in aircraft design were pushing the limits of what human machinists could do. Eventually, one machine shop had enough: faced with manufacturing a helicopter blade part with a decidedly oddball shape, the chief engineer did the only thing he could. The man generated a long table of coordinates, and gave it to three machinists. One read off the list, while the other two dialed in each set of numbers on the mill. It took a while, but the results were better than anyone had managed before.

Of course, the engineer realized the process would be much more efficient

if he could just feed the numbers directly into the machine tools. After a large research & development effort — they ended up using servo technology that had been developed to aim guns in WWII — the first “numerical control” machine tools were born. By the 1970s it was computers, not punch cards, that controlled the machine tools. Nowadays just about every tool imaginable can be computer controlled: not just mills, but also drills, lathes, woodworking and sheet metal tools, foam cutters, plasma/waterjet/laser cutters, even grinders.

Benefits of CNC Machining Riverside

What about simpler parts? With CNC machining Riverside shops

can cut curves just as easily as they can straight lines, and just as accurately. 3D structures are no problem. Equipped with CNC machining Riverside shops need fewer steps to manufacture a part, and setup time for a machine is vastly lower. Many CNC machines have automated tool changers so a machinist doesn’t even have to change tooling. Since they always follow the same instructions, there’s much less room for error in CNC machining too — increasing yield over manual processes.

Of course, even with CNC machining Riverside machinists still have work to do.

Computer control still requires human knowledge and intervention. Most CNC machines aren’t very aware of the environment around them. They have to be told where the raw material is located, otherwise they might just machine through the vise holding it in place. If an error happened somewhere in the programming, a machine might just keep going… destroying the part and maybe even itself. The machinist has to check the incoming data and make sure it will work properly, and then use his or her knowledge to optimize it for the machine. They may have to interpret a drawing to generate tool paths, speeds, and feeds, and then go over the resulting G-code to make sure everything is as it should be. Knowing the intricacies of CNC machining Riverside machinists can get the best possible performance: the maximum tolerances in the minimum possible time with the nicest finish they can achieve.