Is it Really Worthwhile Investing In 5 Axis CNC Machining Temecula

Is it Really Worthwhile Investing In 5 Axis CNC Machining Temecula

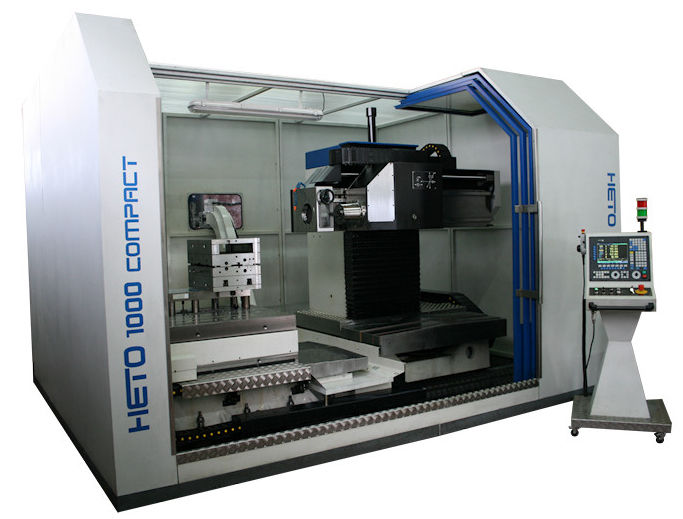

It wasn’t too long ago when manufacturers in Temecula, California were wondering why they should switch to CNC machining from the manual mills that they were already using. Today, when it comes to investing in 5 Axis CNC Machining Temecula technology, the situation is quite similar. Many have been left behind simply due to the fact that they did not switch to CNC soon enough. When it comes to competing effectively and staying a top, it is a must for businesses to invest in the latest technologies.

The term “5-axis” machining center may often confuse people in Temecula. Many manufacturers and shopkeepers think that they do not have the work that would require the use of a 5-axis CNC machine. Considering the fact that 5-sided machining can be facilitated with a 5-axis machining center, there is plenty of which in which using a 5-axis CNC machine can prove to be beneficial. This means that even if there is no simultaneous 5-axis work, more profits can be earned if parts currently being produced using 3-axis machines are produced on a 5-axis machining center through 5-sided machining.

Why Is 5 Axis CNC Machining Temecula A Better Choice?

With 3-axis machines, multiple setups are required for each side of the part, setup time increases and accuracy decreases. On the other hand, when it comes to 5-axis CNC machining, setup time for the production of parts is reduced, accuracy is increased, and shop capability is also expanded for future work.

Is Simultaneous 5 Axis CNC Machining Temecula Is Even Better?

Mold Work

One example where you should definitely consider the use of a simultaneous 5 axis CNC machining Temecula would be mold work, based on the mold. There tends to be limitations if 3-axis machining is used to manufacture the mold, especially when it comes to core molds that tend to be taller or the deep cavity molds. Although a 3-axis machining center can be used for mold work, if the work involves a deep-cavity mold, it becomes essentially to use long and skinny tools. While using these long and skinny tools, the feed rates have to be slowed down so that chatter is minimized and tool breakage is prevented. Often, the quality required quality of surface finish can be achieved when 3-axis machining is used for mold work. For fine finishing operations, particularly when it comes to small molds with a small diameter, the process can become more difficult than necessary if 3-axis machining is used.

When it comes to simultaneous 5-axis machining, shorter and stouter tools can be used, as a result of which pushing faster with greater feed rates becomes possible. If simultaneous 5-axis machining is used for mold work, then heavier cuts can be taken and z-depths do not turn out to become a problem. As a result of all of this, the time frames in using the machine is also drastically reduced.

Conclusion – 5 Axis CNC Machining Temecula can increase production and Profits!

Whatever the case, 5 axis CNC machining Temecula technology is definitely worthwhile for businesses that want to enhance and improve their capabilities of producing parts.

Is it Really Worthwhile Investing In 5 Axis CNC Machining Temecula

Is it Really Worthwhile Investing In 5 Axis CNC Machining Temecula