The differences in Machining Lathe & Milling

There are two basic devices in metalworking, the machining lathe & milling machine. The lathe is one of the world’s oldest machine tools — woodworkers have used lathes for many years to turn ornate figures. The milling machine is a much newer device, and it’s ideal for turning blocks of raw stock into intricately cut parts. Both a machining lathe & milling machine are capable of extremely high precision.

The lathe is designed to remove metal from a spinning piece of raw material

. The lathe holds a section of bar stock in a chuck, and feeds a cutting tool into the surface as the chuck spins. As a result, the lathe tends to produce cuts that have circular symmetry: round holes and cavities inside or round surfaces and cuts on the outside, all centered on the axis of rotation. By smoothly varying the position of the cutting tool as the part turns, lathes cut tapers and ball-shaped ends and cavities. If the cutting tool is moved far enough per rotation of the part, the lathe will cut a thread. These properties have made lathes the traditional choice for producing round or tubular parts.

How the Machining Lathe & Milling machines work.

The milling machine moves the raw material much less than a lathe.

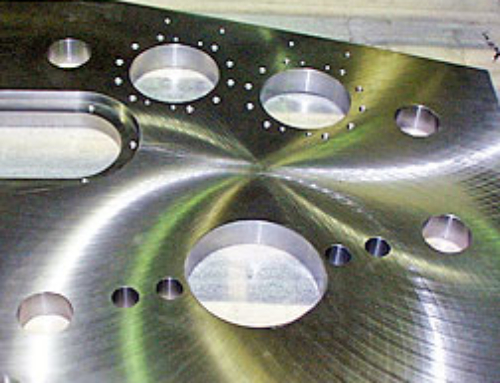

Whereas the lathe spins the part being machined, the milling machine moves it in the horizontal and vertical axes, forcing it against a rotating cutting tool that removes material. (Some milling machines — with four or more axes — can also turn and tilt the part or the cutting head.) This means the milling machine can easily produce holes and slots in the face of the part with whatever shape you may need, whereas a traditional lathe can generally only produce one hole on the central axis. Because it easily handles wide and flat stock, the milling machine’s ability to easily produce rectangular and odd-shaped parts has made it the most popular choice for many designers.

New teleology in machining lathe & milling machines

Improvements in technology means there aren’t as many differences between a machining lathe & milling machine as there once were. Multi-axis CNC machining centers, often built on the milling machine model, can often produce some of the same cuts that used to require a lathe. On the other hand, sophisticated modern lathes can produce features for which you previously needed a mill. Since changing between a machining lathe & milling machine costs time, money, and precision, understanding what your machine shop’s capabilities are means you can design for maximum efficiency. If you’d like to know more about what Temecula Precision can do for you, check out our website or give us a call today.