Techniques Used in Fabricated Metal Product Manufacturing

They also use techniques such as welding and assembling so as to join different metal parts together when doing fabricated metal product manufacturing. This is because they start working with raw metal that is in various shapes and sizes and so, in order to turn it into the specific kind of product that they want. There always is deference in what the industries in this sub sector do. For instance, there are those who use only one method to come up with products while others use a combination of several methods. It is all determined by the technology that they want to employ and the use for which the final products are meant.

Specific Designs in Fabricated Metal Product Manufacturing

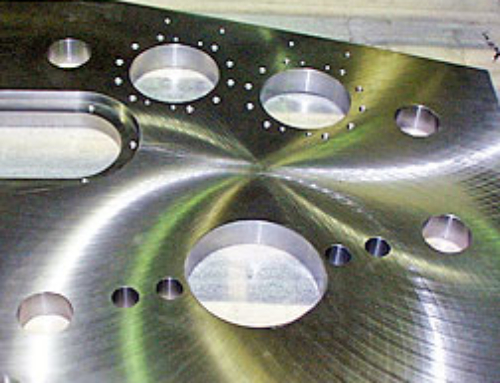

The first step in fabricated metal product manufacturing is to come up with the desired metal shapes. The shapes are usually used as the basis from which the final products will be made. For instance, there are many industries which start by constructing the basic frame when they want to make certain products. They then can proceed from there so as to add several details until they done. Spring and wire industries are the best example of industries in this sub-sector. A look at the way they make their products reveals that they stat by assembling the basic shapes of the springs before they can fabricate them into the final products that they desire.

Sometimes, the industries in the fabricated metal product manufacturing sub-sector share the processes. There are those that do not fabricate the products fully. For instance, you might have realized that some of them are only involved in the making of the basic shapes which they then sell to other industries for further fabrication. Others buy products that are almost finished and add a few final touches before they can sell them. Regardless of what an industry does, the most important thing is to end up with the kind of products that the clients really need.

Something To Consider When Using Fabricated Metal Product Manufacturing

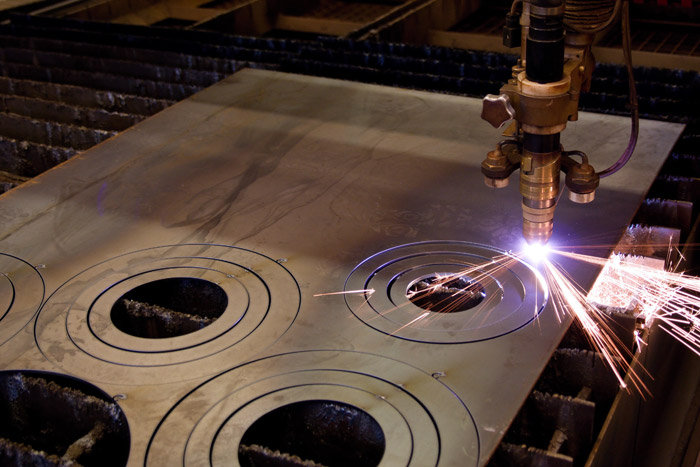

If you are looking for an industry that deals in fabricated metal product manufacturing, you need to consider several things. For instance, you have to be sure about the kind of products that you really need. You also should be sure of what they can do before you trust them with your project. If you want the items to be fabricated very fast, you need to take a look at the kind of equipment that they use to do the work.